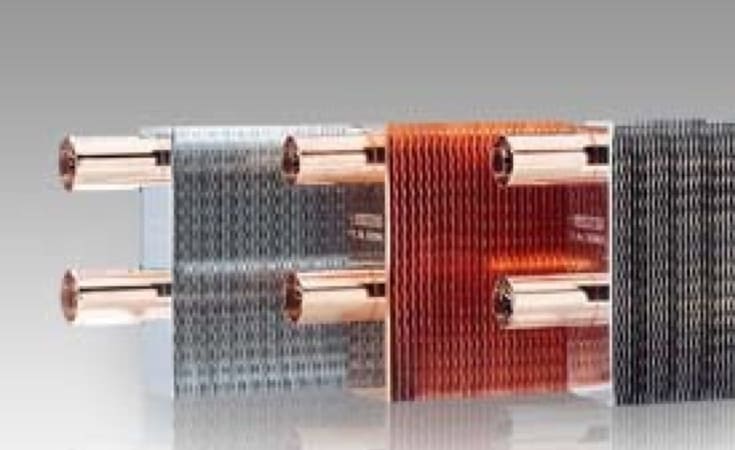

Continuous Rippled & Full-Collared Fins

Hayden provides continuous rippled & full collared fins to offer key advantages over traditional straight-finned models.

Benefits of Full Collared Fins

The rippled construction along the outer edges of our Rippled Fins as well as across the air path provides for:

- Structural rigidity

- Increased surface area

- Better air flow mix

The net result is optimum heat transfer performance. In addition, full collars ensure maximum surface-to-surface contact as the ¾" diameter tubes are mechanically expanded to join and secure the tube and fin assembly. All this means a structurally solid unit that maximizes heat transfer capacity in a compact design.

Standard Fins

Standard fin spacing is 12 fins per inch with optional spacing at 8 or 10 fins per inch. Steel and stainless steel tubes are alternatives to our standard copper tubing. Custom units manufactured with copper or steel fins are also available.

Continuous Rippled Fins Industries

Hayden's Rippled & Full Collared Fins serve a wide range of industries, such as:

- Renewable energy

- Power Generation

- Oil & Gas

- Immersion Cooling

- Automotive

- Agriculture

- Mining

- Marine

- Petrochemical

- LNG

To learn more about our Full Collared Fins, contact us today!

Why we do this

Hayden’s profits help the Ventura Global Health Project

bring direct clinical care to the world’s poor.

Learn More

Learn More